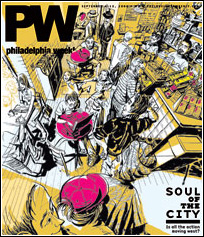

Jig and Real

Tony Santos found his calling at PTR, the United Nations of ironworking.

From the December 3, 2008 Philadelphia Weekly.

Tony Santos struts around the 100,000-square-foot factory in Port Richmond, proudly showing off the machinery as though he's giving me a tour of his own home.

"You see this jig here?" he asks, pointing to a giant steel contraption used to fabricate parts for recycling machines. "Before I built this, they only made one piece per day. Now they build eight pieces or more every day."

Sparks fly from nearby welders. The smell of old grease and fresh paint lingers in the chilly air. The sound of crashing metal echoes through the cavernous plant.

As he escorts me down the assembly line, Santos points to several other jigs he designed for family-owned PTR Baler and Compactor, the largest manufacturer of vertical balers in the world.

"I made this place efficient," he says.

When Santos, 58, started as a general helper at PTR 35 years ago, he was a high school dropout from Salinas, Puerto Rico, who could barely speak English.

"I remember one of the guys saying, 'Hey, give me a clamp,'" Santos recalls. "I thought to myself, 'What the hell is a clamp?'"

***

There was a time when manufacturing jobs were a popular gateway to the middle class.

When Santos joined PTR in 1973, there were around 250,000 factory jobs in Philadelphia. Those without conventional book smarts could find a job with good wages and excellent benefits. The local ironworkers union, of which Santos is a member, represented more than 3,500 workers then. But that was before everyone was expected to earn a college degree, before computers became commonplace and before industrial jobs were shipped overseas en masse.

Today there are around 40,000 manufacturing jobs in Philadelphia. The local ironworkers union has only around 600 members, and 120 of them work for PTR.

Among them are a dozen native Albanians, a few Moroccans and a pair of Cubans, among others. At least eight different languages can be heard on the factory floor.

Santos, who's planning to retire in two years, will collect around $5,000 per month from his pension.

"I never would have imagined this life," he says. "This company has been very good to me."

***

We detour from the assembly line so Santos can show me the first jig he designed and built more than 20 years ago. He leads me to a pair of industrial drill presses. He grabs a strip of plastic, slides it under the press and explains how mounts lock the plastic into place so the drill operator can punch hole after hole without stopping to measure.

"I built this during overtime," Santos says. "My supervisor said, 'If it's good for the company, go do it.'"

Santos left Puerto Rico in 1968 because he needed a job and stumbled into a position at PTR, where his wife worked as a secretary.

As time went on he encouraged friends and family to apply for jobs with PTR. Now he has two cousins, numerous friends and his niece's boyfriend working alongside him. His son did temp work there during a break from college.

"I've been here so long they treat me like one of the family," Santos says.

***

As we approach the finished balers, we run into Gary Fudala, PTR's vice president who started with the company as a welder shortly after Santos began.

"In those days, this place was full of German, Polish and Italian immigrants," recalls Fudala, a Fishtown native. "Tony was the only Hispanic guy. I kind of adopted him."

Fudala tried to teach English to Santos, who was picking up phrases he heard around the factory.

"I remember hearing Tony say, 'Fanculo! Fanculo!' all over the place," Fudala says. "I told him, 'Hey, Tony! That's a bad word.'"

"Everybody was saying it," Santos retorts in his thick accent.

Inside the bustling factory, the two became fast friends. On weekends they went fishing or hunting together. They attended birthday parties for each other's children.

"It's been a good partnership in many ways," Fudala says. A former Army paratrooper, Fudala eventually became an executive with the company.

Santos went from floor sweeper to welder. He designed half the jigs used in the factory. Now he's a team leader supervising a group of 40 welders, fitters and technicians.

"It's America," Fudala says. "You start at the bottom and work your way to the top."

"I work real hard," Santos adds. "That's the kind of place it is. They take care of their workers."